SALES AND OPERATIONS PLANNING (S&OP) A PERFORMANCE FRAMEWORK by Scott C Ambrose Despite a robust body of practitioneroriented literature focused on the importance of balancing customer demand with product supply within companies, there is very little empirical research suggesting how to achieve it Sales and Operations planning (S&OP) is a tacticalS&OP is a key component of Connected Planning and a very good place to begin They both aim to use data to harness the true potential of businesses to drive growth If you're not sure what Connected Planning is or why it's important for your organisation, then make sure to contact a member of our team today S&OPTop content on Demand Planning and S&OP as selected by the Supply Chain Brief community

Sales And Operations Planning A Project Manager S Guide Asana

S&op planning is usually done by

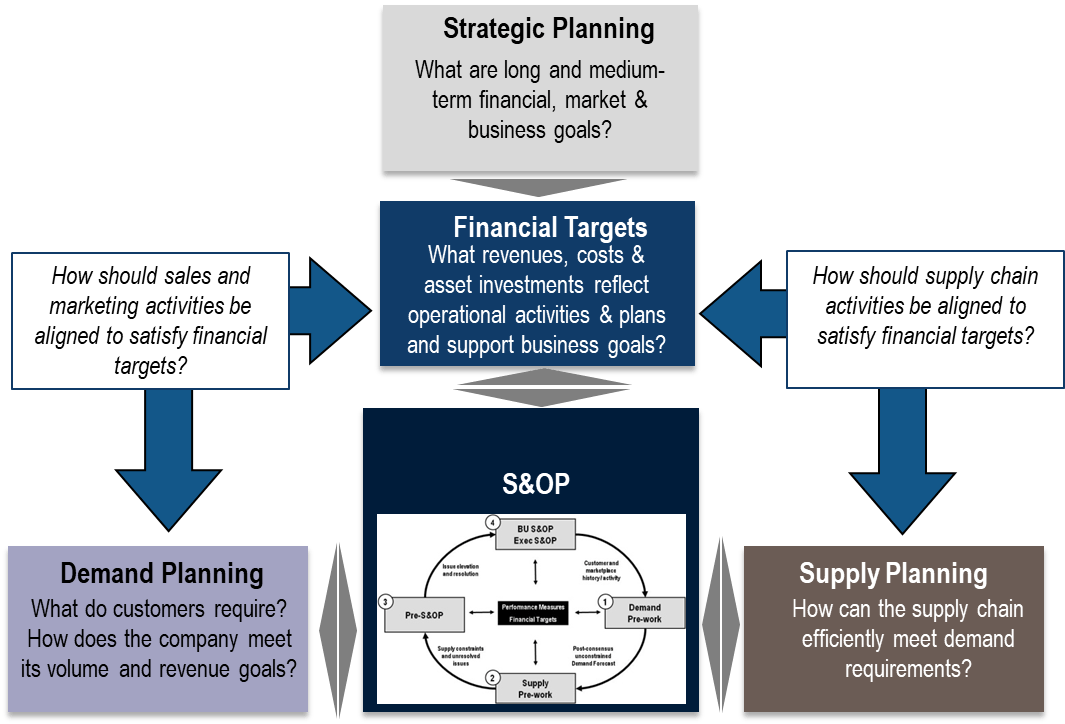

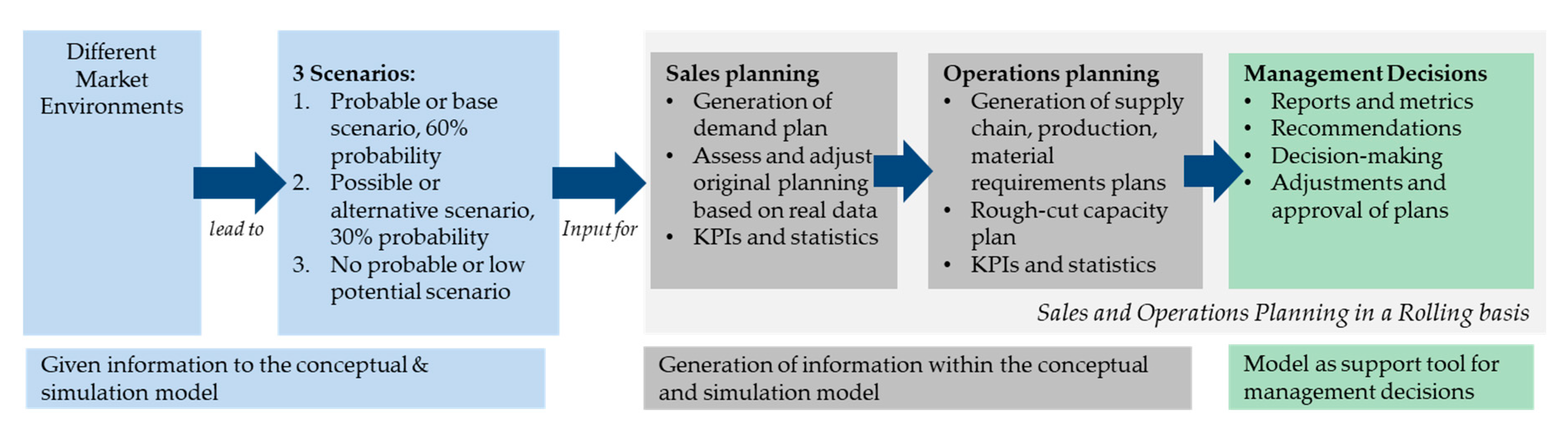

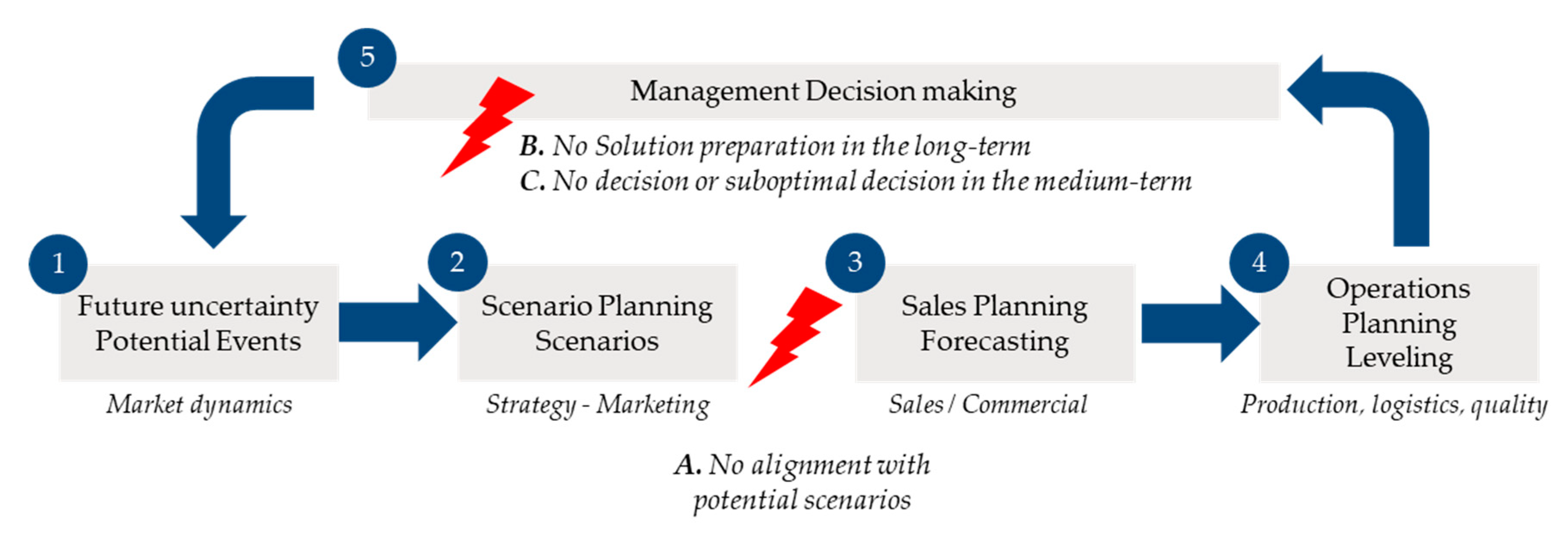

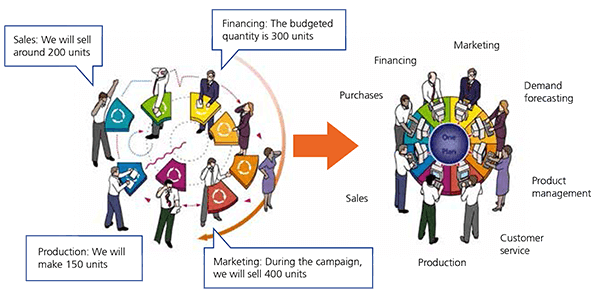

S&op planning is usually done by- S&OP is a never ending recurring business planning process that often operates in a VUCA (Volatile, Uncertain, Complex and Ambiguous) world and is impacted by continuous internal or external threats and challenges For S&OP to run effectively, you need to be clear, focused and committed to what you're trying to achieve You need to have the right state of mind, rise to any Sales and Operations Planning (S&OP) A integrated business process that drives collaboration, focus and alignment across multiple divisions and departments in a company 5 • Demand plans • Financial goals • Supply plans • Inventory quantities • New product plans S&OP brings together Inventory 6

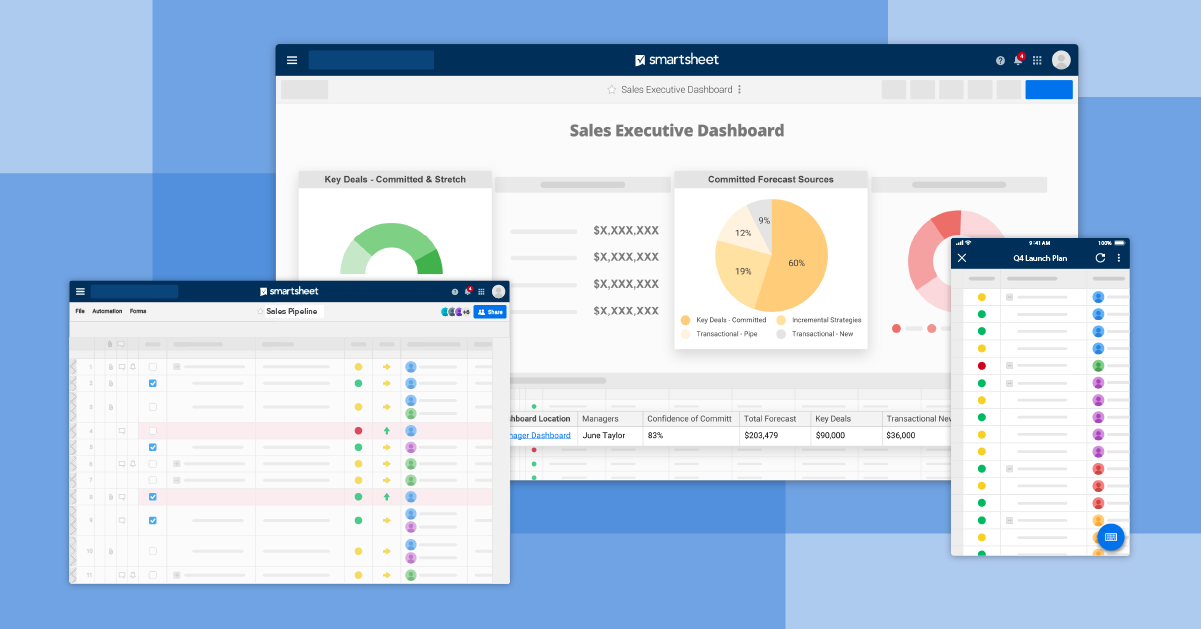

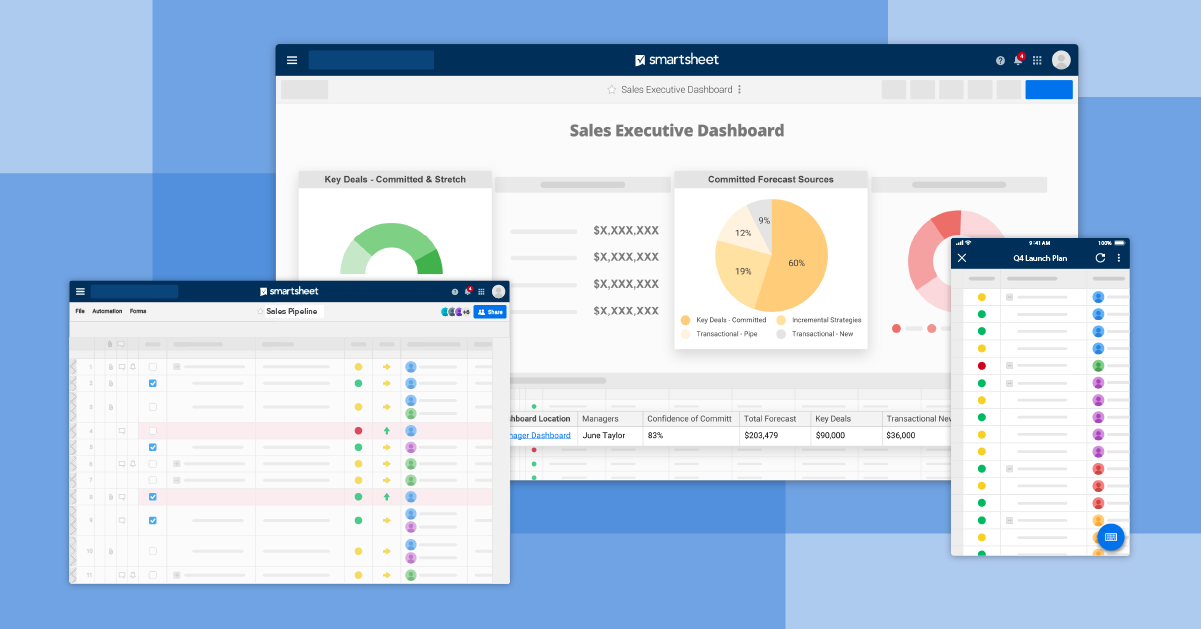

Sales And Operations Planning S Op 101 Smartsheet

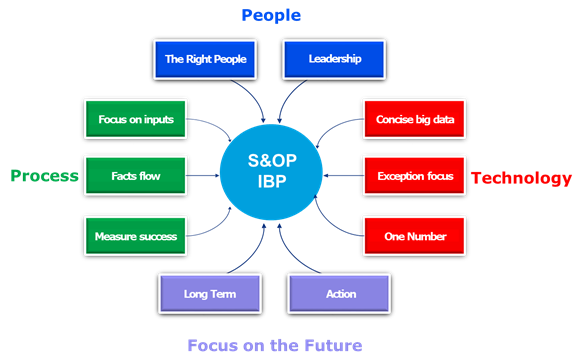

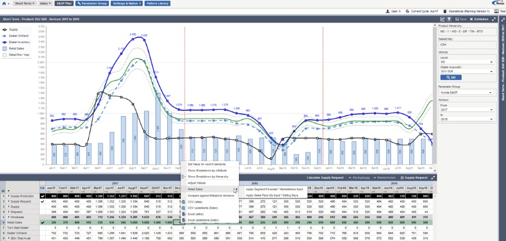

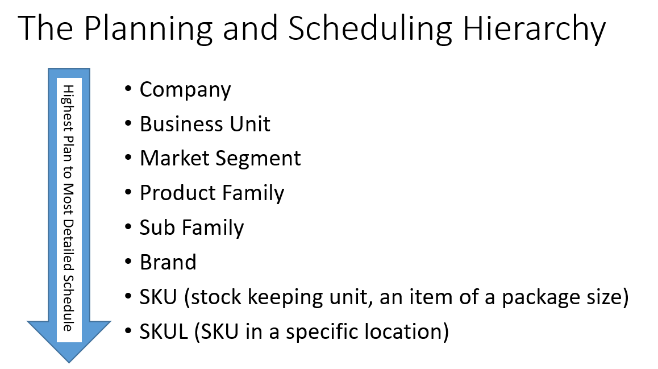

S&OP – Planning Worksheet 66 S&OP – Information Flow S&OP Spreadsheet Demand Information Supply Information Summarised by family, sub family, by month, In lbs Order fill % Shortages KPI Actuals Prod Pln KPI Forecasts Actuals Util % OT Inventory Ad To Plan Capabilities Outages Constraints Production Distribution Inventory Issues Orders Shortages Issues OrdersQuestion S&OP Planning Is Usually Done By This problem has been solved!S&OP is a strategic business process, and there are building blocks, such as organization, incentives, people and technology, critical to making it effective A traditional S&OP process involves internal company stakeholders from different disciplines—typically operations, sales, marketing and finance—to anticipate and synchronize demand and

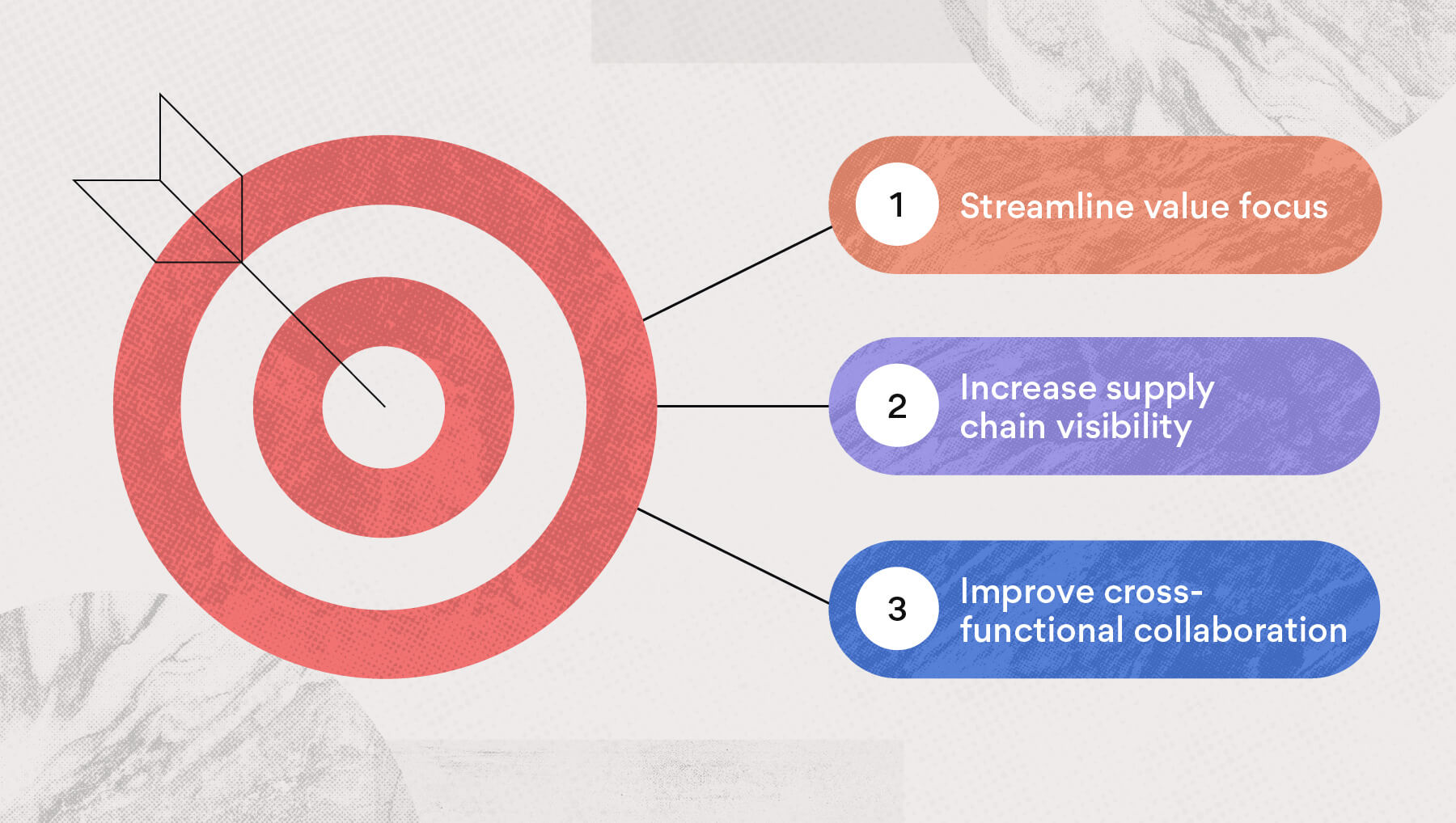

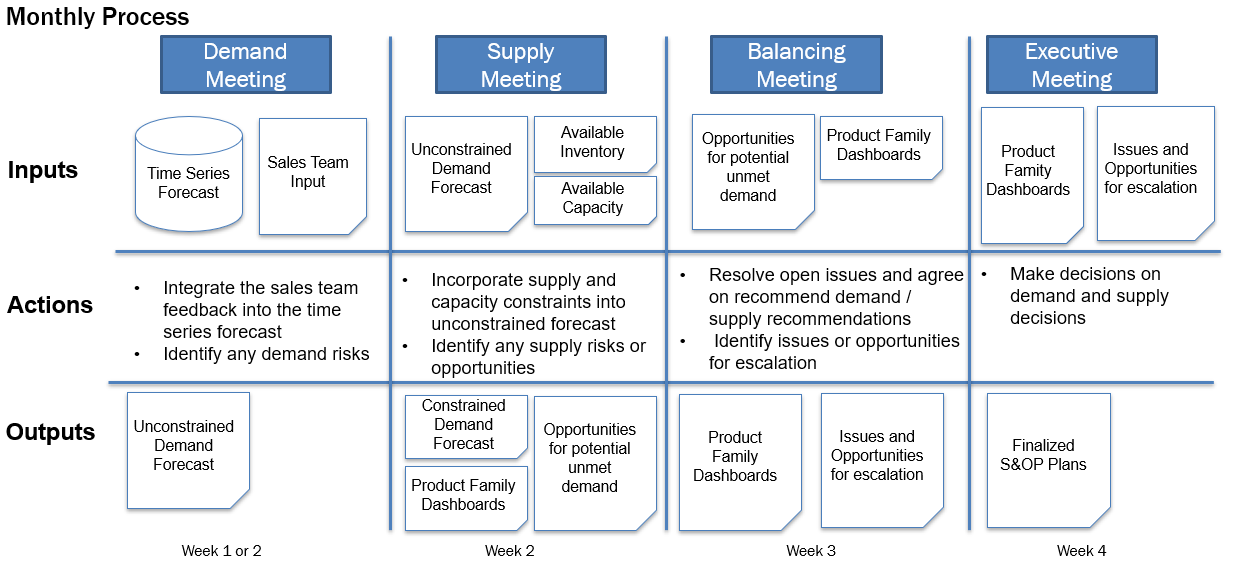

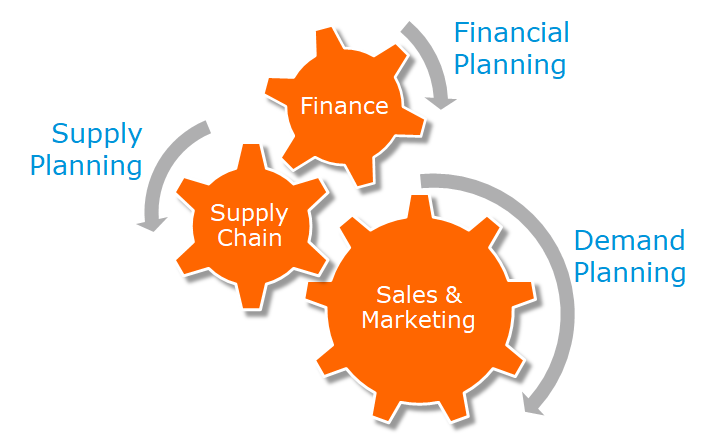

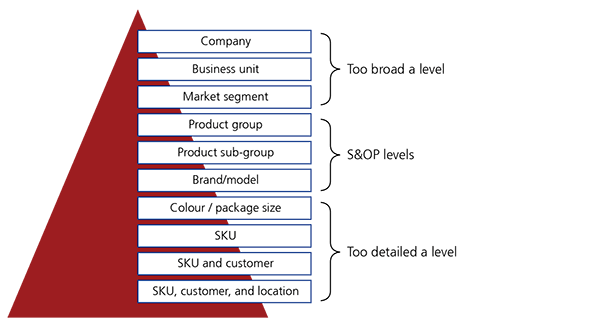

Sales and operations planning is an aspect of supply chain planning whose goal is the creation of a unified, consensusbased business plan It draws input from an organization's key functional areas, including sales, marketing, manufacturing, distribution, and finance Crossfunctional collaboration results in plans that all stakeholders understand and are committed to supporting S&OP plans are reviewed by product family, using the common unit of measure This provides a consistent communication base across all functions and entities;A) S&OP is also called an aggregate plan B) S&OP is used to determine which plans are feasible in the coming months and which are not C) S&OP is typically done by crossfunctional teams that align competing constraints

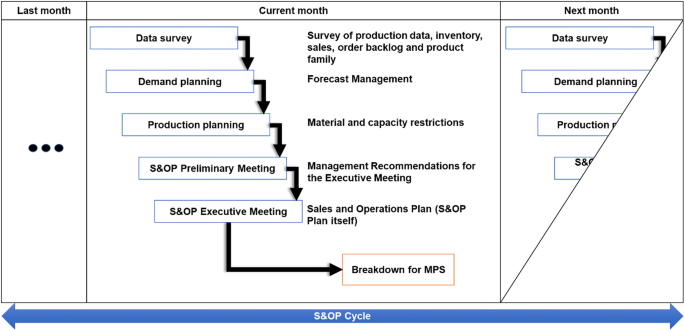

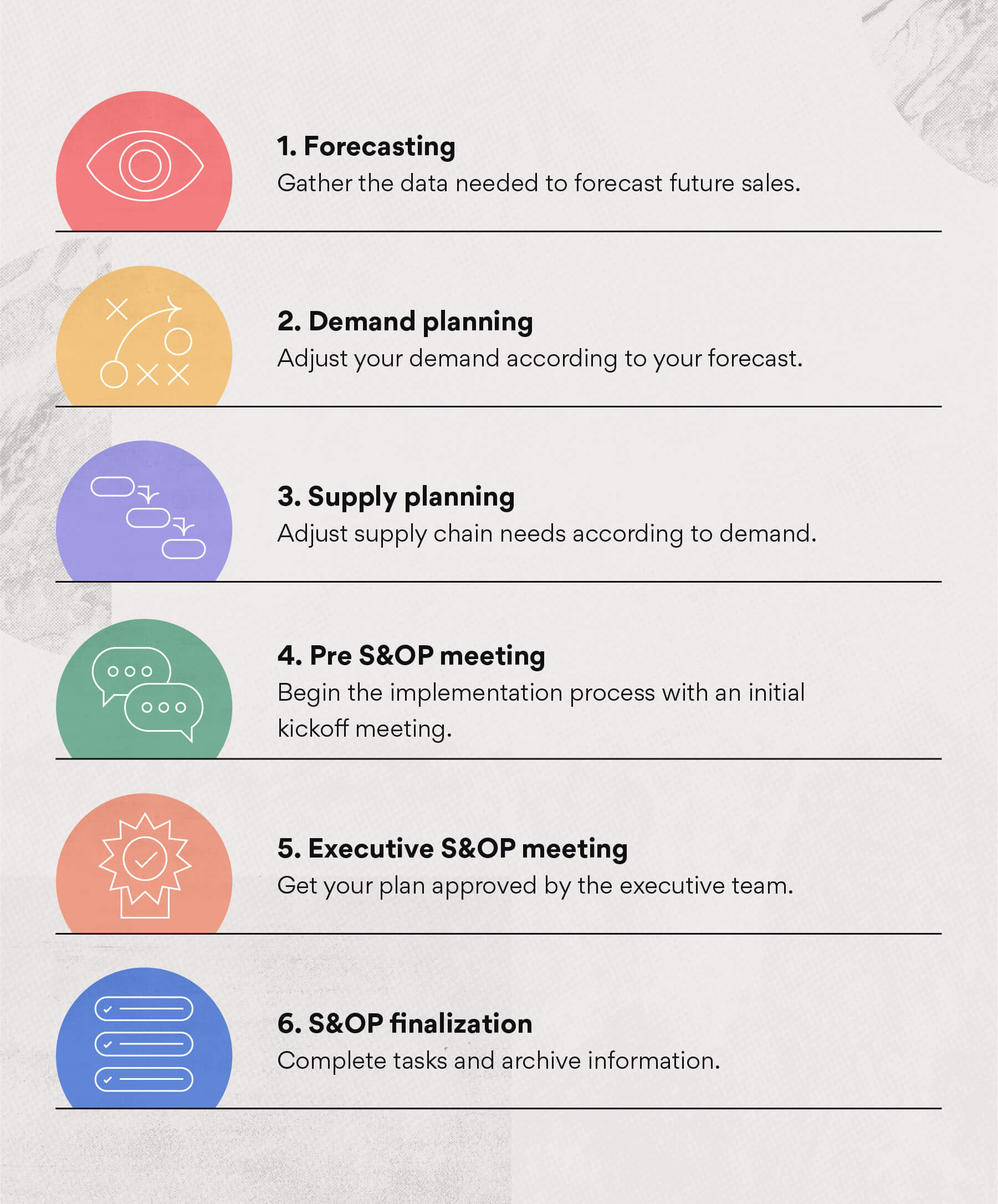

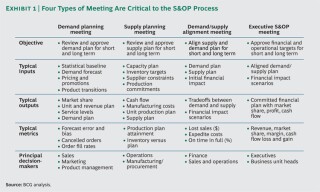

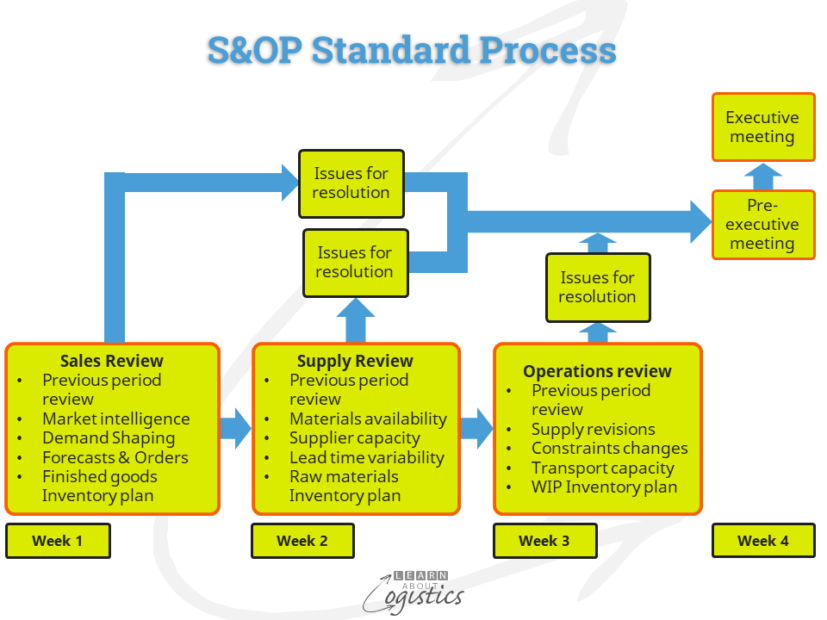

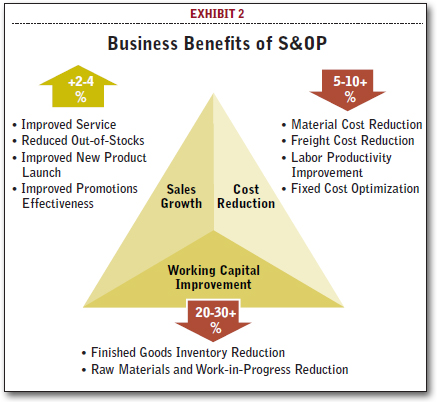

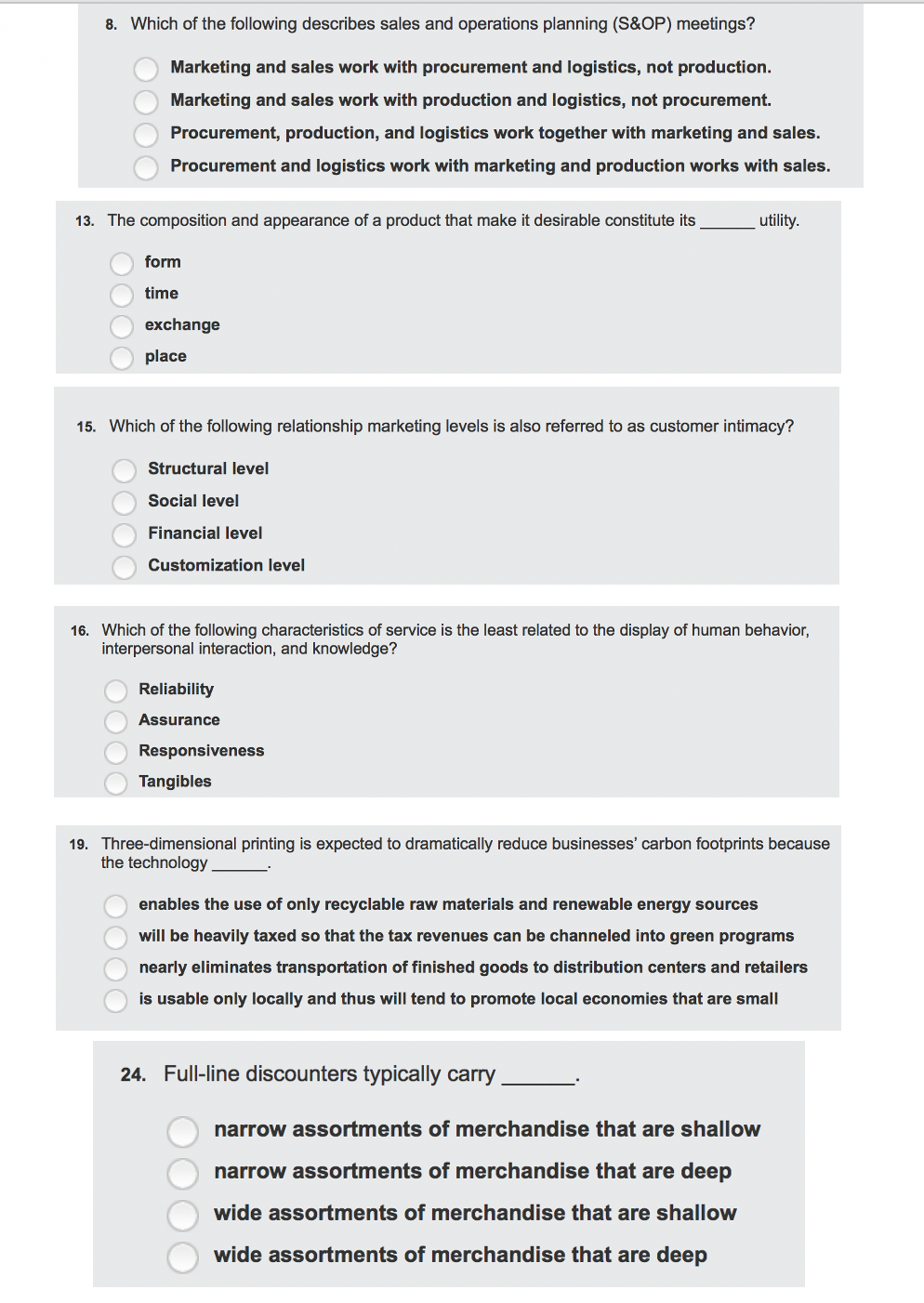

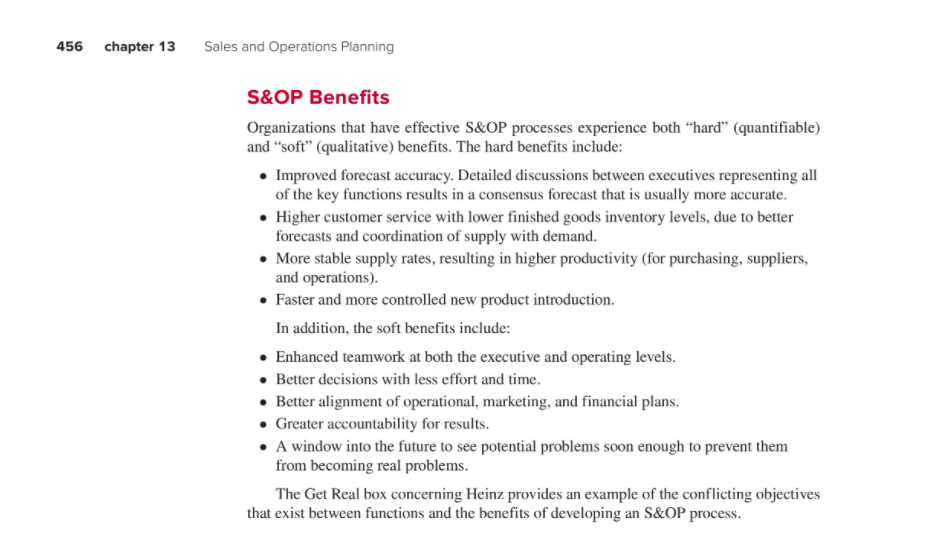

Sales and Operations Planning (S&OP) A process that helps firms provide better customer service, lower inventory, shorten customer lead times, stabilize production rates, and give top management a handle on the business Designed to coordinate activities in the field with the manufacturing and service functions that are required to meet demand over time A process The (S&OP) process consists of a lot of leg work to support the three main meetings Pre S&OP Demand, Pre S&OP Supply, and the S&OP meeting itself (OK, some companies have a fourth one The Executive S&OP meeting) The whole process is designed to allow a company to make the best possible plan for the future based on current estimates, as well as prepare for certain contingencies via whatif scenario planning However, things do Sales and Operations Planning (S&OP) Sales and operations planning (S&OP) is a business management process where leadership and executive teams meet to ensure each business function is aligned to balance supply and demand S&OP requires crossorganizational collaboration to create detailed forecasts for predicted sales

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

1

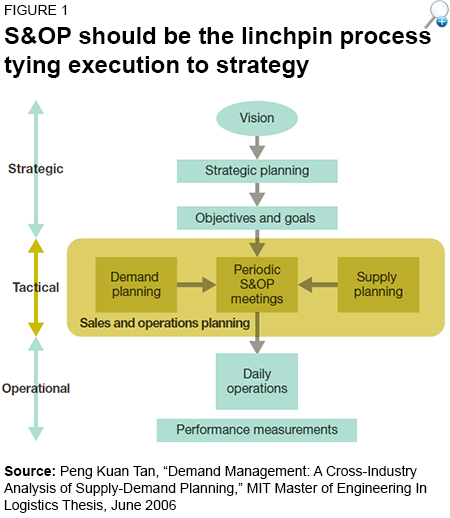

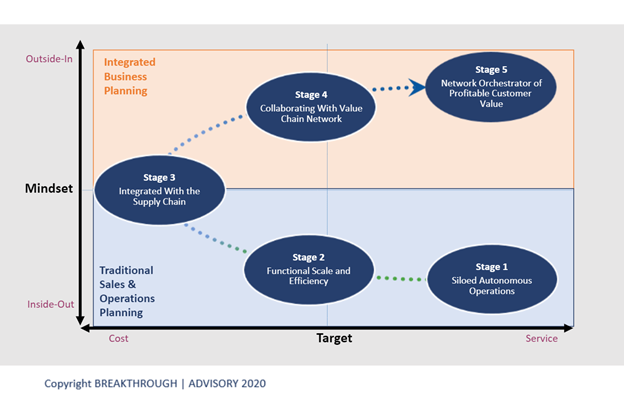

3 future challenges in Supply Chain planning and S&OP (Part 3) The study highlights the outstanding role of a companywide integrated Sales & Operations Planning process as a driver for sustainability, customer orientation and profit maximization Therefore S&OP is an increasingly important element of strategic and operational corporate management It is of particular interestTop content on S&OP, Sourcing and Supply Chain Planning as selected by the Supply Chain Brief communityInput to S&OP process is demand plan, inventory, capacity requirements and supply constraints The owners of the process than churns out and identify requirements for material procurement, capacity investment, man hours, estimated revenue, subcontracted capacity requirement etc An efficient and collaborative S&OP process is one of the most important pillar of planning process

Sales And Operations Planning Relex Solutions

What Is Sales Operational Planning Enchange

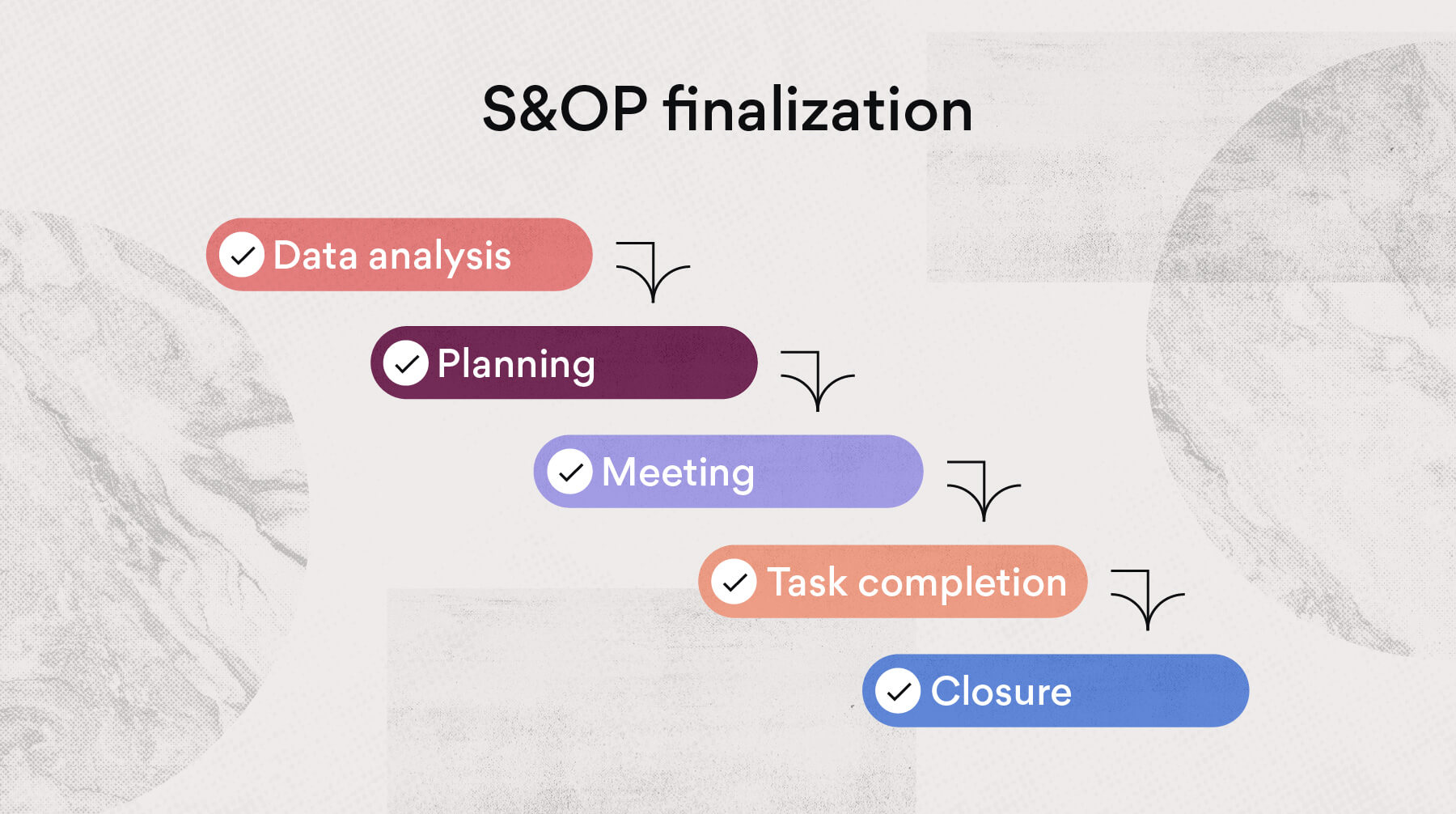

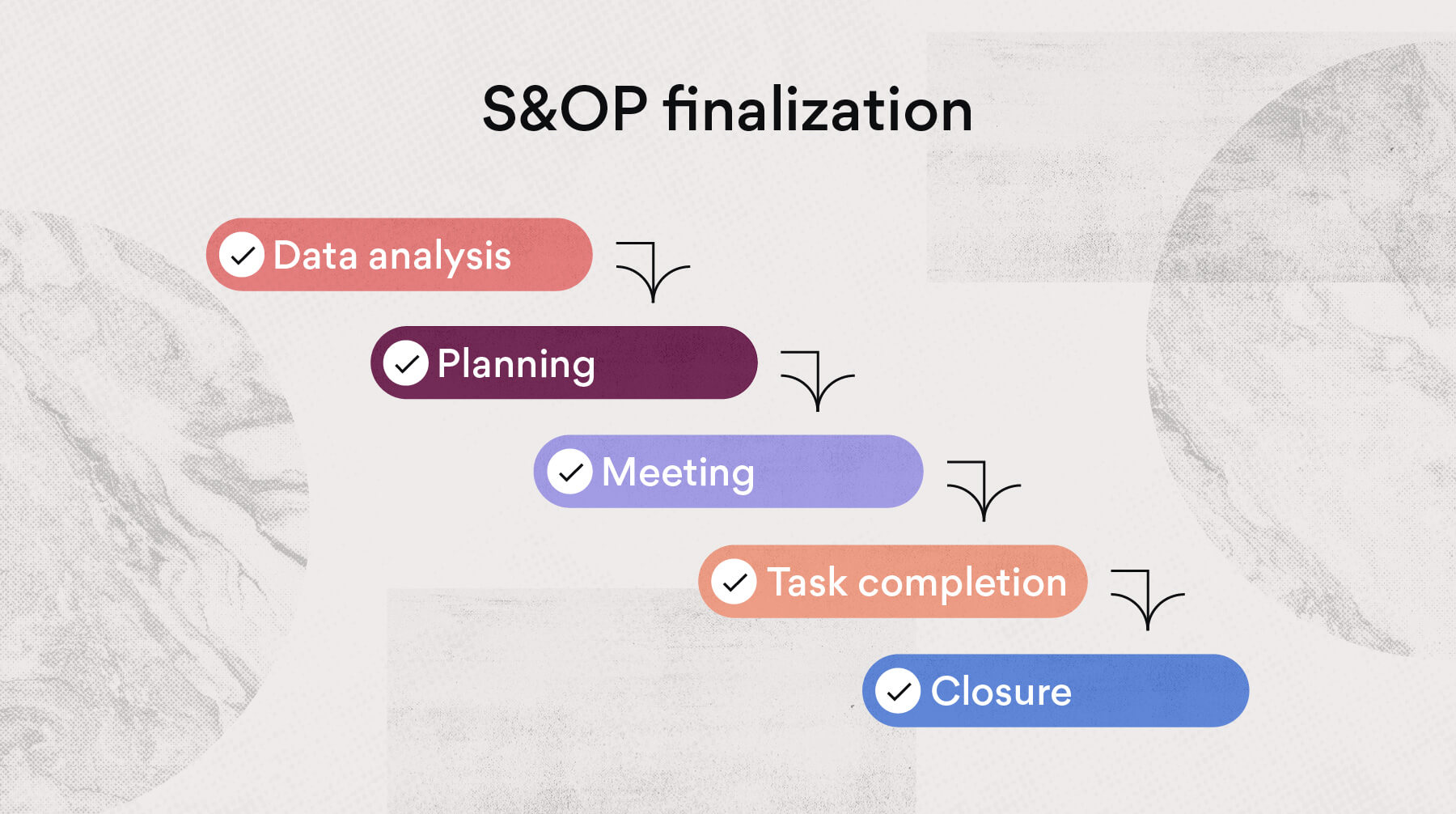

S&OP is a structured monthly process that aligns all functional areas under a unified set of assumptions to enable and coordinate decision making It integrates demand, supply, operations, and financial planning into one game plan for businessTo accomplish the demand and supply balance Sales and Operations Planning Steps to S&OP There are two distinct phases to S&OP 1) process design, and 2) process conduct In the design phase, all of the technical workings are engineered, and in the conduct phase S&OP is used as a business management process The following 10 stepsThe S&OP planning process should always be built on a realistic foundation, as the base line determines the trustworthiness of the S&OP plan That is why the operational plan should integrate towards IBP for S&OP (preferably via HANA Cloud Integration, HCI) HCI allows you to integrate data from your legacy system to IBP for S&OP applying translation rules for both master data and

Successfully Integrating S Op In Your Organization Industrystar

Are You Suffering From S Op Churn Optimity Software

Sales & Operations Planning is the process by which we bring together all the plans for the business (Customers, Sales, Marketing, Development, Manufacturing, Sourcing, and Financial) into one integrated set of tactical plans S&OP gives management the ability to direct its business to achieve a sustainable competitive advantageSales and Operations Planning (S&OP) is a corporate practice intended to deliver superior supply chain execution by leveraging a deeper alignment with other divisions beyond supply chain most notably sales, finance and production The practice usually revolves around a monthly process starting from the sales forecasts and ending with quantified A good executive S&OP process will have all these characteristics If it does, S&OP should be improving your demand plan If it doesn't, now is the time to get the process tuned up and break out of the OS&P cycle Contact us to find out how DBM is a global thought leader with over years of S&OP consulting experience

Sales And Operations Planning A Project Manager S Guide Asana

S Op Families By Constraint

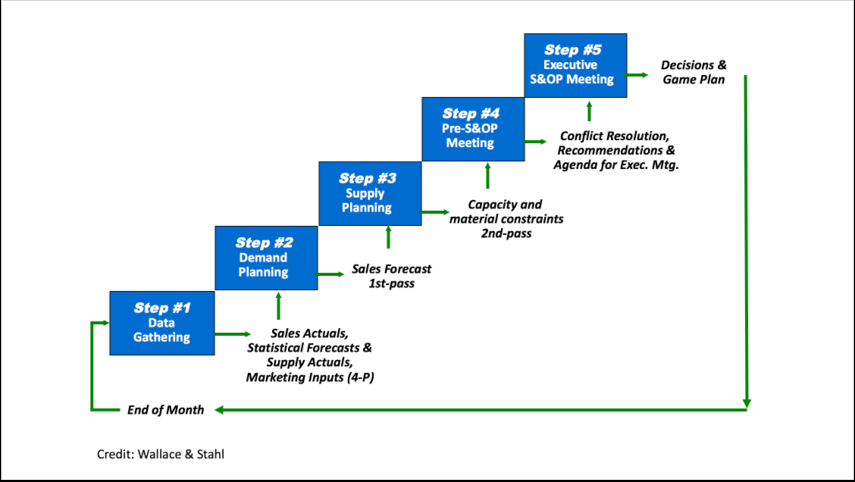

Foreseeing the future is thought to be impossible;The planning horizon for S&OP usually extends between 6 and 18 months into the future with the 12 month mark as the average, coinciding with financial budget cycles (Wallace & Stahl, 08) The process is generally implemented using some semblance of the steps described next (Grimson & Pyke 07;JDA Sales& Operations Planning (S&OP) helps in taking a crossfunctional approach to integrated business planning that unites all the moving parts across a supply chain with a shared focus to meet demand across markets, with an eye on both immediate and longterm strategic goals When risks, opportunities or threats interfere with strategic

Smoother Execution Through S Op Logistics Management

Successful Change Management Adds Value To Your S Op Process Implement Consulting Group

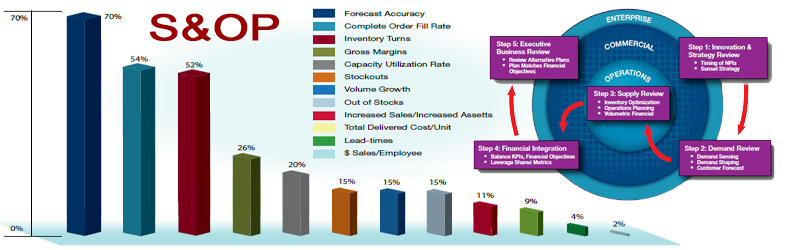

S&OP Answering Six Fundamental Questions in One Graph Updated Jun 18 A printable PDF is available here If you follow any of the work/writing that we do on S&OP, you will quickly realize that we believe data to be an important part of the S&OP process At the center of our philosophy on S&OP is the 5Section SheetHe Sales and Operations Planning (S&OP) process has been around for quite some time I started including it in many of my presentations on forecasting in the mid1990s As I polled audiences along the way, I found that about onethird of the early ones had implemented an S&OP at their company, while lately, the number has been hovering over 80% Clearly the S&OP Sales and operations planning (S&OP) is a popular process that aligns a company's diverse functions while balancing supply and demand S&OP gives executives a comprehensive overview of the business so they can grasp where it stands (in all its complexity) This allows them to continuously match highlevel strategy with daytoday operational tactics in all departments

The Fully Integrated S Op In Supply Chain Planning Context Download Scientific Diagram

Pdf Sales And Operations Planning S Op An Overview

S&OP, or sales and operations planning, is an integrated business management process that drives organizational consensus to balance supply and demand The S&OP process, which typically happens monthly, aligns operational areas – such as sales, marketing, product development, manufacturing, procurement, finance, and accounting – so they work inAttendance and p articipa tion usually do not become a problem 2 Executive S&OP is a decisionmaking process that b alances demand and supply at the aggregat e level, aligns operationalSales and Operation Planning (S&OP) might just be one of the most complex planning processes there is, including demand, supply and inventory planning Its aim is to match what businesses buy or produce, with what they plan to sell

What S Wrong With S Op Toolsgroup

5 Reasons Why Sales And Operations Planning Is Important Scmdojo

Danny Smith, Steelwedge's VP of Industries, helps companies leverage Integrated Business Planning (IBP) and Sales and Operations Planning (S&OP) processes to meet their strategic goals He has a year track record of using technology to solve realworld business problems, most recently as Oracle's global solution champion for IBP As a Strategic PlanningDemand Optimization versus Demand Planning S&OP processes which are driven by a layer based approach look at demand planning as the first step of a demand planning implementation The focus of this approach is towards enabling the ability to generate demand forecasts at a SKU/Location combination or maybe at a higher level of the product hierarchy for a period of sayShort for Sales and Operations Planning, S&OP is an integrated business management process that aligns all facets of an organization to their key market goals, synchronizing them and allowing the organization to react with agility to changes in the market Through S&OP, the executive/leadership team achieves continuous focus and alignment among all functions of the

The 5 Most Common Sales Operations Planning Mistakes And How To Avoid Them Supply Chain 24 7

Sales And Operations Planning S Op 101 Smartsheet

Sales and operations planning (S&OP) is an integrated business management process through which the executive/leadership team continually achieves focus, alignment and synchronization among all functions of the organizationThe S&OP process includes an updated forecast that leads to a sales plan, production plan, inventory plan, customer lead time (backlog) plan, new productYet, sales and operations planning (S&OP) users seek to do just that by strategically and tactically directing businesses to achieve competitive advantage In fact, many companies successfully took advantage of S&OP to survive the worldwide economic downturn and remain profitable When APICS The Association for OperationsSales and Operations Planning (S&OP) process As discussed in Part I, S&OP has been receiving a lot of attention for the past couple of years There are a number of industrywide studies in the area Companies are recognizing its value in improving the tactical and operational planning to prepare the supply chain for meeting anticipated customer demand S&OP appears to be driving

What Is Sales And Operations Planning S Op Plex Demandcaster

Solved Question 1 Sales And Operations Planning Deals With Chegg Com

Wagner et al, 14) First, data is gathered typically at the end of the The type of planning that is usually done by top management and is for a period of five years or more into the future, is known as A) Operational planning B) Shortterm planning C) Strategic planning D) Intermediate planning Categories Questions Leave a Reply Cancel reply Your email address will not be published Comment Name Email Website Save my name,S&OP production plans by family become inputs to the Operations planning tool (Master Schedule or similar term) in the ERP system To reduce uncertainty in supply chains, the ideal situation is for the Master Schedule to become input to the suppliers' S&OP process and those suppliers do

How S Op Improves Your Organization Tmc Fr

Sales And Operations Planning A Project Manager S Guide Asana

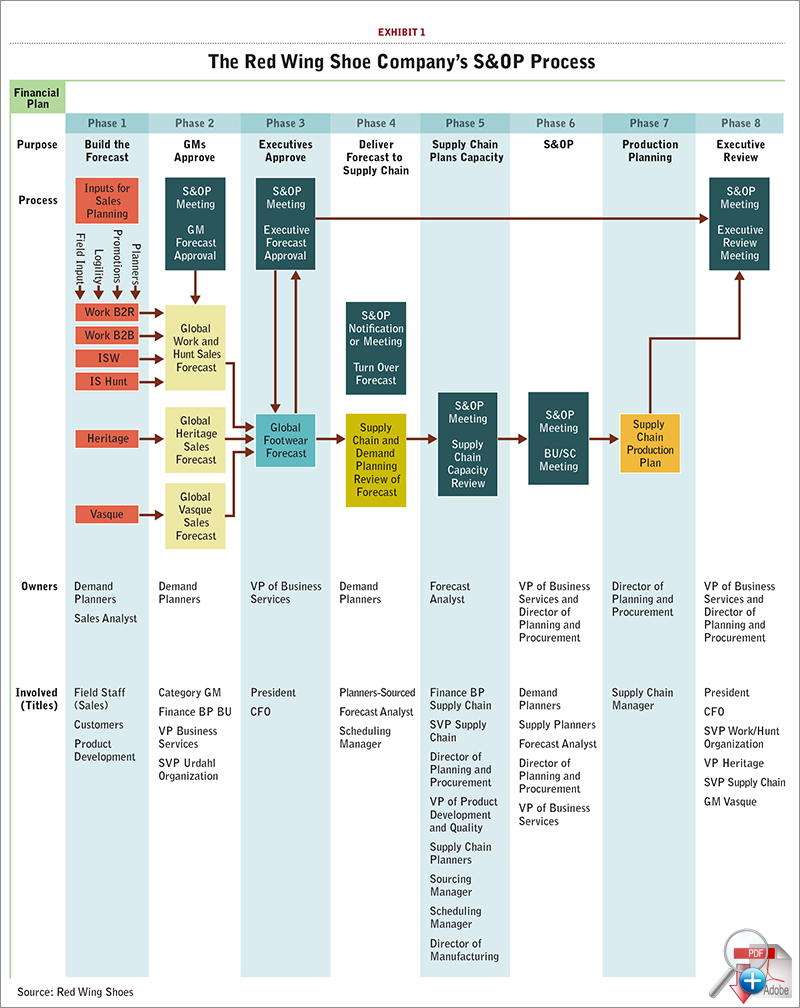

S&OP stands for sales and operation plan and sales and operations planning at the same time It is both a plan and the process that creates, implements, monitors, and continuously improves the plan The S&OP process involves a series of meetings to meet a consensus A demand and production plans that reflect the results of demandside sensing and influencing activities andImplementing Sales and Operations Planning (S&OP) In our knowledge article What is S&OP?, we explained what sales and operations planning (S&OP) is and its many advantagesTo sum up, S&OP is the creation of a unified, consensusbased business plan that enables organizations to control inventory costs while vastly improving service levels Let's review Planning is one of the four functions of management that allows a manager to develop and implement strategic action steps aimed at reaching an organizational goal There are three

Fixing An Overly Complicated Sales And Operational Planning Process Supply And Demand Chain Executive

Ultimate Guide To Sales And Operations Planning S Op In 21

See the answer S&OP planning is usually done by Expert Answer Answer 1) Sales and operations planning (S&OP) is a cycle for better coordinating a producer's stockpile with demand by having the sales division work together with operations to make a solitary creat view the full answer Previous A monthly or weekly operations meeting S&OP is a formal process of monthly nearterm planning meetings focussed on the organisation and requiring attendance by all interested parties The process is driven on behalf of the most senior executive by the master planner It brings together the executive team to sign off the future plan of the organisation

Aggregate Planning And Sop 13 Power Point Presentation

Sales Operations Planning S Op Software Optimity

What Is Sales And Operations Planning S Op Quora

1

Climbing The Sales Operations Maturity Ladder Consumer Goods Technology

Applied Sciences Free Full Text Predictive Sales And Operations Planning Based On A Statistical Treatment Of Demand To Increase Efficiency A Supply Chain Simulation Case Study Html

S Op A New Frontier For Supply Chain Resilience 05 14 Cscmp S Supply Chain Quarterly

Advanced Planning System As Support For Sales And Operation Planning Study In A Brazilian Automaker Springerlink

Supply Chain Graphic Of The Week The S Op Process

Sales And Operations Planning

Sales And Operations Planning A Project Manager S Guide Asana

Hierarchical Supply Chain Planning S Op To Execution Supply Chain Link Blog Arkieva

Back To Basics The Importance Of S Op

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Sales And Operations Planning Relex Solutions

What Is S Op How S Op Works Demand Planning Com

Sales Operations Planning Consulting Supply Velocity

Sales And Operations Planning For The Food Supply Chain Case Study Sciencedirect

Advanced Analytics For Sales Amp Operations Planning Analytics Magazine

What Is The Value Proposition Of Sales And Operations Planning

S Op 3 0 The Future Of Planning Supply Chain Trend

How To Master Sales And Operations Planning S Op

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Stock Level Of Finished Products S Op Plan Download Scientific Diagram

Sales And Operations Planning

Applied Sciences Free Full Text Predictive Sales And Operations Planning Based On A Statistical Treatment Of Demand To Increase Efficiency A Supply Chain Simulation Case Study Html

Sales And Operations Planning Explorescm

What Is S Op How S Op Works Demand Planning Com

What Is Sales Operations Planning Supply Chain Minded

Sales And Operations Planning S Op Transform Your Business

What Is Sales And Operations Planning S Op Plex Demandcaster

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales Operations Planning Why Is S Op Important

What Is S Op Sales And Operations Planning Sap Insights

Pdf Sales And Operations Planning Maturity What Does It Take To Get And Stay There Semantic Scholar

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

Getting To Grips With Sales And Operational Planning Bloor Research

Achieve Excellence In Sales And Operations Planning Sapinsider

Sales Operations Planning Drives Manufacturing Efficiency

A Common S Op Process For Your Business Helps Planning Learn About Logistics

The Evolution Of Sales Operation Planning

Good Sales And Operations Planning Is No Longer Good Enough Bain Company

What Is S Op How S Op Works Demand Planning Com

What Is S Op By Accenture Strategy Guest Blogger

Who Should Own Sales And Operations Planning I Kinaxis

Is Your Erp Hurting Your Sales And Operations Planning

3 Primary Components Of Sales Operations Planning People Process And Technology Supply Chain 24 7

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

What Is S Op The Origins Use And Value Of Sales Operations Planning

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Operational Plan Example

A Comprehensive Overview Of Sales And Operations Planning S Op

Involving Execution Managers With Sales And Operations Planning Supply Chain 24 7

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

7 Reasons Why S Ops Fail Solvoyo

Ibp Transforming S Op From Good To Great

Sales And Operations Planning A Project Manager S Guide Asana

Where Is The E In S Op Sales And Operations Planning Adexa

Sales And Operations Planning Relex Solutions

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Lean S Op Sales Operations Planning Four Principles

What Is S Op Sales And Operations Planning Explained Anaplan

Oracle Demantra Sales And Operations Planning User Guide

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Pdf Sales And Operations Planning Part I The Process Semantic Scholar

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

Solved 8 Which Of The Following Describes Sales And Chegg Com

Sales And Operations Planning The Fundamentals For Success

Improving Profitability With Sales Operations Planning Magellan Consulting Group

Sales And Operations Planning Relex Solutions

Solved Answer Briefly Chapter 13 This Chapter Addresses Chegg Com

Chapter 13 Aggregate Planning And Sop 14 Pearson

Integrated Business Planning Ibp S Op Evolution Agile Innovation

How To Select The Best Sales And Operations Planning S Op Software For Your Business In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

What Is S Op How S Op Works Demand Planning Com

Top Performer Benefits Of Effective Sales Operations Planning Supply Chain 24 7

1

A Comprehensive Overview Of Sales And Operations Planning S Op

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

S Op And S Oe A Symbiotic Relationship

Why S Op Needs In Memory Computing Toolsgroup

0 件のコメント:

コメントを投稿